Overview of Popular PCB Assembly PCBA Inspection. Are there Specific Design Considerations for MCPCB.

What S The Difference Between Pcb Immersion Gold And Gold Plating Plating Gold Gold Plate

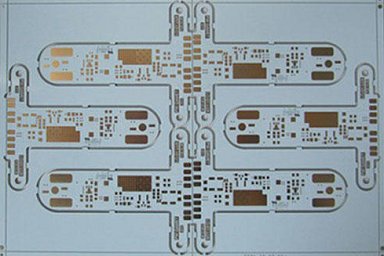

The basic structure of MCPCB comprises of the following.

. Aluminum-based PCB is the most common type of metal core PCBs for its cost advantage. IPC 6012 class 2 Quality and performance. For the ultimate phase utilize a nail artwork glue to adhere the bow in your nail.

Solder Mask Circuit Layer Copper layer 1oz. What Is Printed Circuit Board PCB Manufacturing. This specification covers qualification and performance of rigid printed boards including single-sided double-sided with or without plated-through holes multilayer with or without blindburied vias and metal core boards.

The mechanical structure is made with insulating materials laminated between layers of conductive material. The IPC-2221 is a general standard that envelops every aspect of the PCB design. History of Flexible Printed Circuit FPC Electronics Industry Trade Show 2020 About PCB Design Fab.

This a single seems like you have got tiny stones for nails. Higher class may result in higher production cost. Th ree Main Categories to consider.

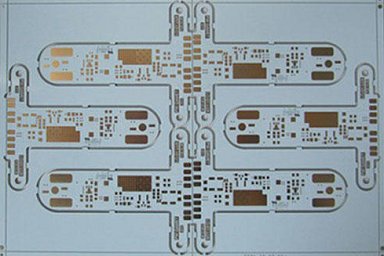

You can also download it here. A strong understanding of our manufacturing ability enables our clients to achieve the special features that their designs require while maximizing efficiency with regard to both time and money. The major benefits of using metal core PCBs are.

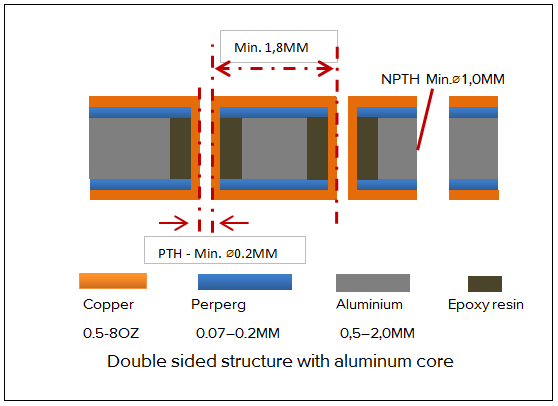

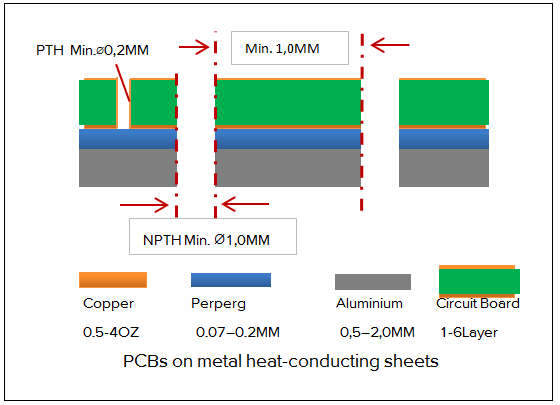

If the board needs to have high speedhigh frequency circuit blocks then using the backside metal plate as a large ground plane provides some shielding. 10 rows General specifications for Aluminum PCBMetal core PCB in A-TECH. Using Metal Core Printed Circuit Board MCPCB as a Solution for Thermal Management FA where A constant Ffailurerate E activation energy in electron volts eV K Boltzmanns constant 863 x 10 eVK T junction temperature in Kelvin If a device with activation energy E 065eV were operating at 50 C and its temperature raised to 60 C.

PCB Industry During COVID-19 Epidemic 2020. To 2oz Dielectric Layer Metal Core Layer Heat Sink Types of Metal Bases used in MCPCBs Aluminum substrate The aluminum printed circuit boards offer good heat dissipation and heat transferring ability. PCB Assembly Design for Testing DFT Manufacturability DFM.

The IPC-2221 also explores the thermal design and ways heat dissipates from the PCBs. Chip On Board Metal Core CB MCPCB is used in thermoelectric separation application Th e Micro-chip or die is directly in touch with the metal core where the heat dissipate. 1500 New Customer Introductory Credit.

It addresses final finish and surface plating coating requirements conductors holesvias frequency of acceptance testing and quality conformance as well as. Consulting these DFM guidelines during your design process will allow you to plan a PCB that conforms to the capabilities of itteles facilities. It comes with a special substrate material that helps boost the design sturdiness of devices working at high temperatures.

Metal core PCBs have a distinctive thickness compared to other boards. It can also provide some plane capacitance if a power plane is used in the board. Manufacturing Printed Circuit Boards Since 1985.

Metal Core PCB MCPCB or sometimes Thermal PCB is a technology developed to overcome the. The PCBs can expel surplus heat from devices. Metal core pcb design guidelines.

It makes the copper PCB even more powerful in real applications. Especially in solid-state lighting aluminum PCBs helps achieve higher lighting levels with less quantity of. Metal Core PCB Design Guidelines.

It helps to blend dielectric polymer layers in high thermal conductivitymaking them suitable for low thermal resistivity. PCBA Boards can be reworked and repaired. Design guidelines Pattern classes represent the PCB complexity.

You want to design Metal Core PCB you should know T-Guard for performance by Best PCB they have excellent design guide for MCPCB from single layer to double layers through Multi-layers MCPCB. PCB design and manufacturing are indivisible sides. T-guide for Performance T-guide for Manufacturability Single Layer IMpcb Fabrication Guideline.

Also this standard considers how conductor clearance and PDN bus layouts should be on the PCB. PCBA rework and repair basis Rework and repair of PCBA must be performed in accordance with PCB design documents and repair regulations and there also must be a unified rework and repair process. However only reasonable operations based on scientific guidelines can guarantee the quality of PCBA boards.

The required quantity of copper affects the flatness of a metal core. Just increase a small drop to the nail and press the bow on it. On each side the PCB has copper substrate or foil and the middle is sandwiched of a copper circuit board for high thermal and electric conductivity.

Most commonly used 1oz. Give it a couple of minutes to dry. Grounding the Metal Core The metal backing on a PCB can act like a large ground plane or a large heat sink.

Metal Core Pcb Design Guidelines In Altium. Get Your Fast Online Quote Now. Designing a multilayer steel core PCB is usually a troublesome process when you dont have entry to.

And electrically interconnect the trace of circuit board wire bonding so thermal conductivity of COB MCPCB is more than 200 Wmk. The MCPCB or metal core PCBs are manufactured around epoxy resin due to its adhesive capacity.

Pcb Design Steps Complete Guide Cirexx

King Credie Printed Circuit Board Pcb Manufacturing Online Quote

Metal Core Pcb Design Mc Pcb Design Expert With Complete Design Guide

King Credie Printed Circuit Board Pcb Manufacturing Online Quote

The Basics Of Metal Core Pcb Design And Manufacturing Nwes Blog

Your Guide To Flexible Pcb Design Layout

Illustration Of The Oe Pcb Design With Main Features Noted Download Scientific Diagram

0 comments

Post a Comment